- General

-

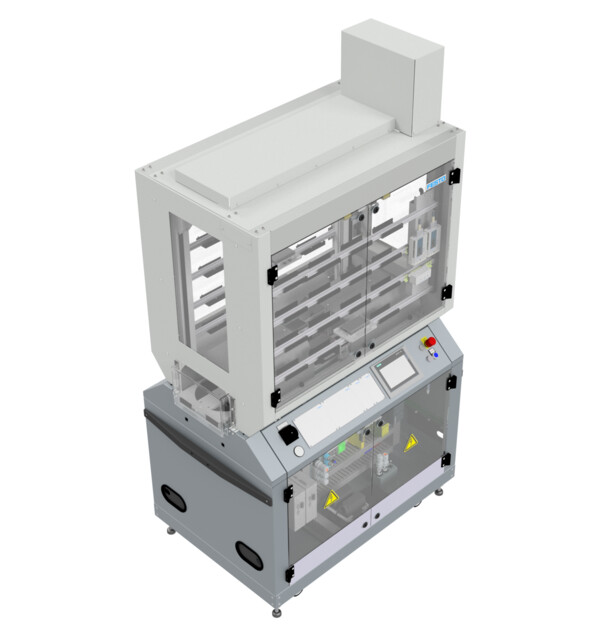

Order number D12002 Type code CPF-B-ASRS32-P Series CP Systems Sub series CP Factory Categories Station, Logistics

- Description

-

The Automatic Storage and Retrieval System (ASRS) is equipped with a cartesian robot for automatic storage and retrieval of pallets. Up to 32 pallets can be stored and retrieved. Two parallel conveyors move in opposite directions, each has one working position where pallets can be retrieved from or put on carriers.

-

Attribute Value Electrical connection CEE (16 A) for connecting to room infrastructure

Preconfigured modular plug for connecting to another CP Factory stationPneumatic connection Hose coupling for connecting to room infrastructure

Preconfigured modular plug for connecting to another CP Factory stationOperating voltage 230 / 400 VAC Operating pressure 6 bar Controller Siemens CPU 1512SP HMI Siemens Simatic TP700 Comfort Network switch Siemens Scalance XB008 I/O 26 DI / 14 DO onboard 2x Stopper unit Pneumatic stopper cylinder with one end-position sensor

4x Carrier detection & identification: inductive

RFID Read-Write-Head2x Belt drive 24 VDC motor

Bi-directional controller with slow and high speedStorage robot X-axis Servo motor Festo EMMS-AS-55-M-LS-TS

Servo controller Festo CMMP-AS-C2-3A-M3 via PROFINETStorage robot Z-axis Servo motor Festo EMMS-AS-55-M-LS-TSB

Servo controller Festo CMMP-AS-C2-3A-M3 via PROFINETStorage robot Y-axis Pneumatic

2x end-position sensorStorage robot revolving axis Pneumatic

2x end-position sensorStorage robot gripper Parallel gripper

Pneumatic

2x end-position sensor

Optoelectrical sensor for detecting pallets on shelfNumber of shelf positions 32 RFID Turk TBEN-S2-2RFID-4DXP bus node with 2 read-write-heads Other sensors 4x carrier detection: optoelectrical Dimenions (H x W x D) 1800 mm x 1200 mm x 800 mm -

Integrated PLC

Description Reference Datatype Address Inputs FALSE = Emergency stop button pushed (n.c.) +K1-F2-KF1 Bool %I0.0 TRUE = Safety doors closed +U1-F2-KF3 Bool %I0.1 TRUE = Emergency stop button pushed +S-F2-FQ1 Bool %I0.3 TRUE = Carrier detected at belt 2 entry +G1-BG36 Bool %I0.6 TRUE = Carrier detected at belt 2 exit +G1-BG37 Bool %I0.7 TRUE = Stopper 1 in lower end position +G1-BG20 Bool %I1.0 TRUE = Carrier detected at stopper 1 / Stopper 1 carrier ident code bit 0 detected +G1-BG21 Bool %I1.1 TRUE = Stopper 1 carrier ident code bit 1 detected +G1-BG22 Bool %I1.2 TRUE = Stopper 1 carrier ident code bit 2 detected +G1-BG23 Bool %I1.3 TRUE = Stopper 1 carrier ident code bit 3 detected +G1-BG24 Bool %I1.4 TRUE = Carrier detected at belt 1 entry +G1-BG26 Bool %I1.6 TRUE = Carrier detected at belt 1 entry +G1-BG27 Bool %I1.7 TRUE = Stopper 2 in lower end position +G1-BG30 Bool %I2.0 TRUE = Carrier detected at stopper 2 / Stopper 2 carrier ident code bit 0 detected +G1-BG31 Bool %I2.1 TRUE = Stopper 2 carrier ident code bit 1 detected +G1-BG32 Bool %I2.2 TRUE = Stopper 2 carrier ident code bit 2 detected +G1-BG33 Bool %I2.3 TRUE = Stopper 2 carrier ident code bit 3 detected +G1-BG34 Bool %I2.4 TRUE = Y-axis retracted +U1-BG46 Bool %I2.6 TRUE = Y-axis extended towards shelf +U1-BG47 Bool %I2.7 TRUE = Revolving cylinder in end position 0° +U1-BG50 Bool %I3.0 TRUE = Revolving cylinder in end position 180° +U1-BG51 Bool %I3.1 TRUE = Gripper closed & pallet gripped +U1-BG52 Bool %I3.2 TRUE = Pallet detected at shelf space +U1-BG53 Bool %I3.3 TRUE = Pallet present on carrier at stopper 1 +U1-BG54 Bool %I3.4 TRUE = Part present on carrier at stopper 1 (not being evaluated) +U1-BG55 Bool %I3.5 TRUE = Pallet present on carrier at stopper 2 +U1-BG56 Bool %I3.6 TRUE = Part present on carrier at stopper 2 (not being evaluated) +U1-BG57 Bool %I3.7 Outputs TRUE = Drive belt 1 in forward direction +K1-QA1:A1 Bool %Q0.0 TRUE = Drive belt 1 in reverse direction +K1-QA1:A2 Bool %Q0.1 Select belt 1 speed (FALSE = normal, TRUE = slow) +K1-QA1:A3 Bool %Q0.2 TRUE = Drive belt 2 in forward direction +K1-QA2:A1 Bool %Q0.4 TRUE = Drive belt 2 in reverse direction +K1-QA2:A2 Bool %Q0.5 Select belt 2 speed (FALSE = normal, TRUE = slow) +K1-QA2:A3 Bool %Q0.6 TRUE = Move stopper 1 down +G1-MB20 Bool %Q1.0 TRUE = Move stopper 2 down +G1-MB30 Bool %Q2.0 TRUE = Retract y-axis +U1-MB50 Bool %Q3.0 TRUE = Extend y-axis towards shelf +U1-MB51 Bool %Q3.1 TRUE = Move revolving cylinder to 0° +U1-MB52 Bool %Q3.2 TRUE = Move revolving cylinder to 180° +U1-MB53 Bool %Q3.3 TRUE = Close gripper (grip pallet) +U1-MB54 Bool %Q3.4 TRUE = Open gripper (release pallet) +U1-MB55 Bool %Q3.5 -

-

-

-