- Function

-

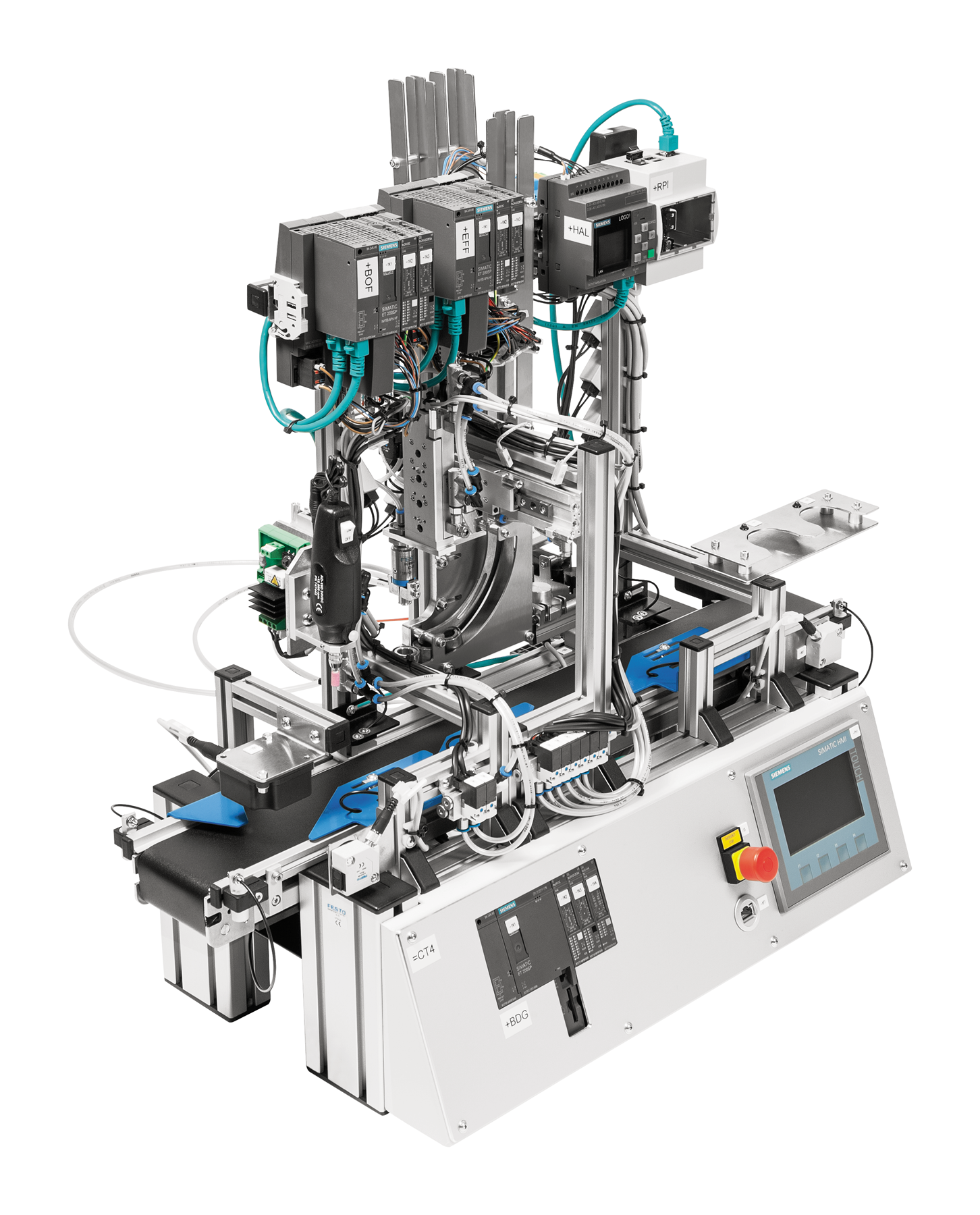

The MPS transfer system serves as a basis for the MPS TS Compact Trainer I4.0. A CPS (cyber-physical system) is set up with currently available automation components. A modern S7-1500 industrial controller is at the heart of this autonomous and highly communicative unit. The PLC is programmed via the TIA Portal. The KTP400 display and control unit serves as a user interface for intuitive operation and machine operator guidance. Data is exchanged with the intelligent workpiece (a bearing roller) via an RFID read-write system which communicates with the controller via an IO-Link interface. The PLC is equipped with an integrated web server for fast process diagnostics with standard IT technologies.

- Layout

-

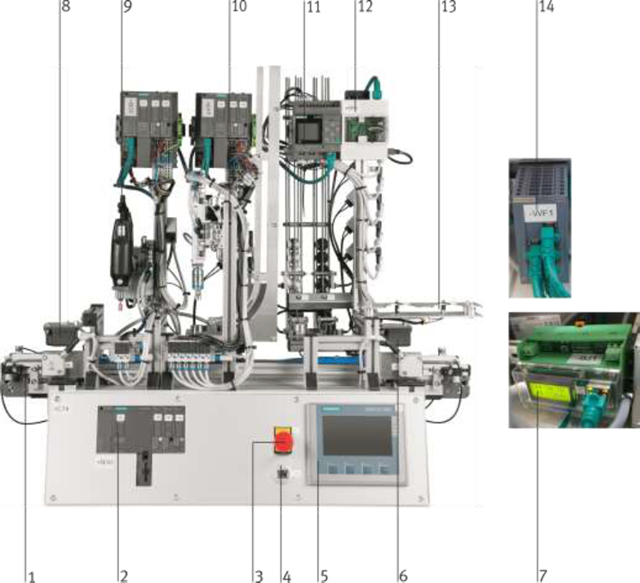

The Compact Trainer I4.0 integrates the following main components in the spirit of the smart factory.

- Elemente

-

1 Transfer line, beginning of conveyor -

2 S71512SP F 1PN main controller -

3 Emergency off pushbutton 4 RJ45 network access-

5 KTP400 display and control unit -

6 RFID reader, end of conveyor 7 DC wattmeter, at back-

8 RFID reader, beginning of conveyor -

9 Drilling module with ET200SP Profinet IO-Device -

10 Insertion module with ET200SP Profinet IO-Device -

11 Pick-by-light module manual workstation with LOGO!8 mini -

12 Raspberry Pi single-board computer -

13 Manual workplace, tray -

14 Scalance XB005 network switch, at back