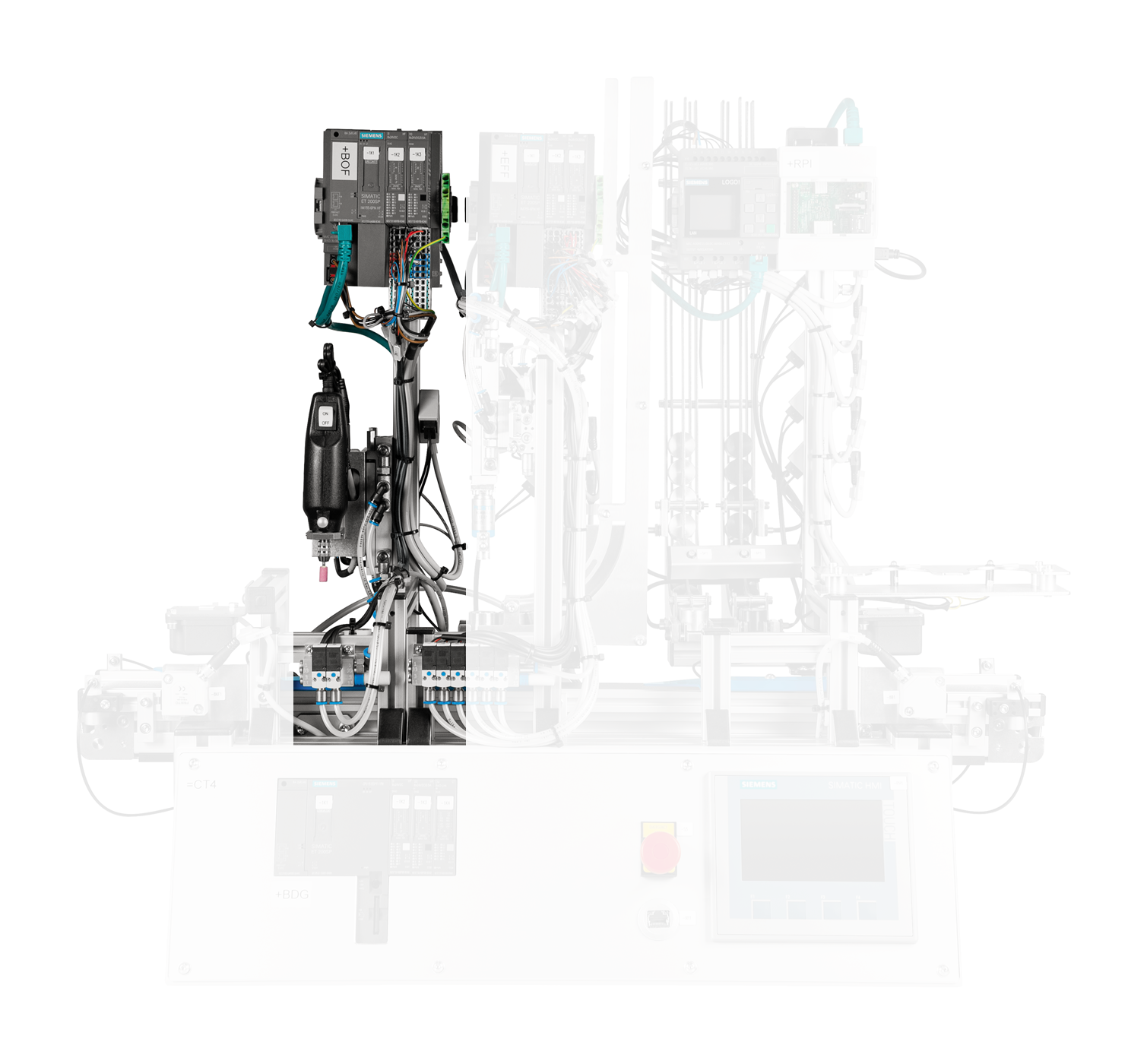

Drilling Module

- Function

-

The task of the drilling module is

- to move workpieces to the correct position and

- to machine the workpiece by adding a drill hole (simulated).

The module drills workpieces (symbolically). The workpieces are detected on the conveyor belt by an optical diffuse sensor. The drilling machine is moved down by means of a pneumatic slide.

Advancing and retracting speed of the linear slide can be infinitely adjusted with the help of one-way flow control valves.

If a workpiece is positioned underneath the drilling machine by the transfer system via the baffle plate, and if the fiber-optic cable at the baffle plate detects the workpiece, the conveyor belt is stopped and an automatic sequence is started. The linear slide moves down and symbolically drills a hole. The linear cylinder then travels back up to its initial position. When the linear slide is at the top, the conveyor belt is re-started and the workpiece leaves the module.

- Pin Allocation Table

-

BMK ET200SP Profinet‑Device Designation +BOF IP-Adresse: 192.168.0.11 Installation location -1B1 I100.0 Reed switch, linear slide, drill up -1B2 I100.1 Reed switch, linear slide, drill down -4B1 I100.3 Through-beam sensor, workpiece in module -1M1 Q100.0 Solenoid coil, linear slide, drilling machine up -1M2 Q100.1 Solenoid coil, linear slide, drilling machine down -11Q1 Q100.2 Starting current limiter for drilling machine power-up