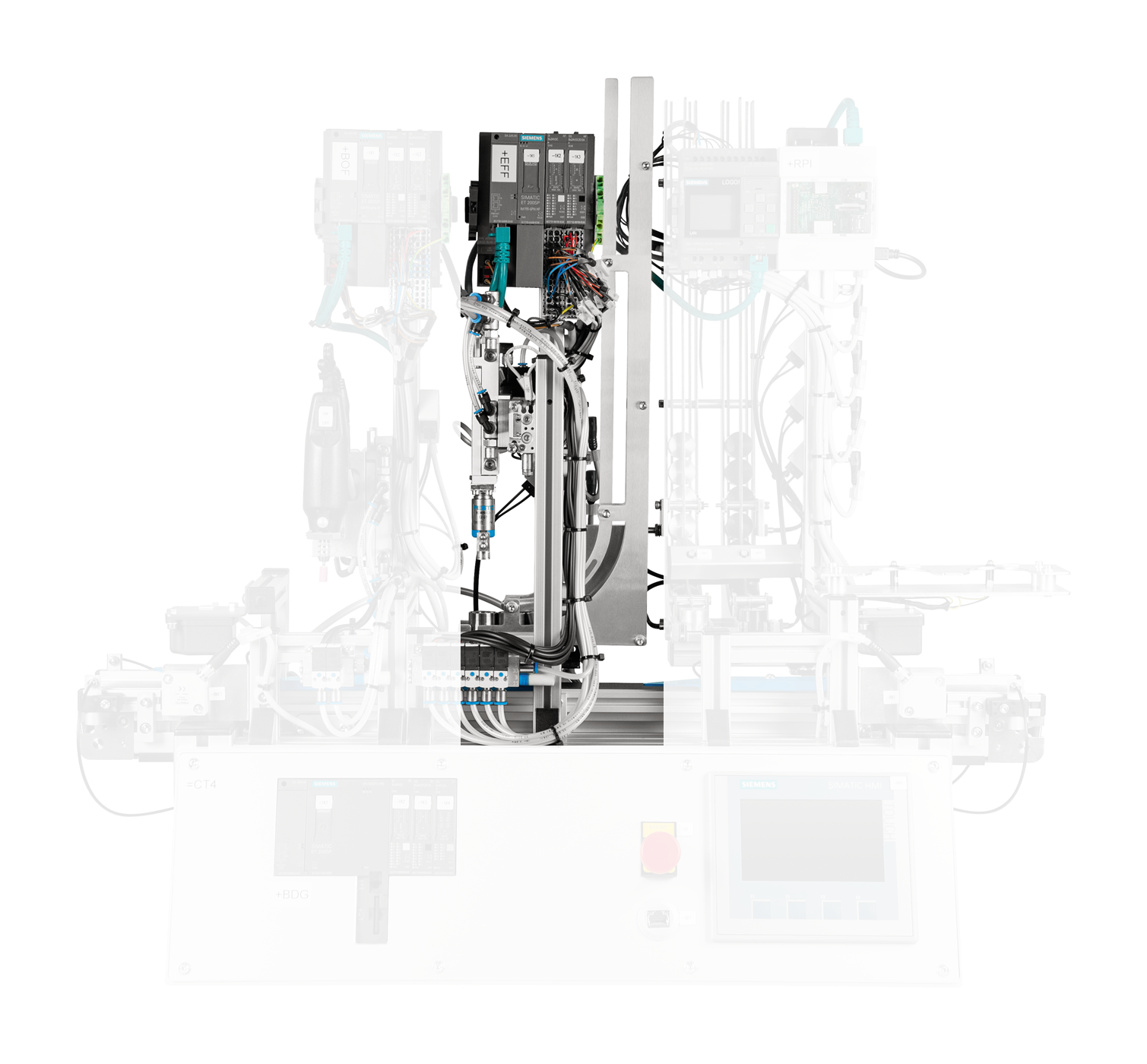

Insertion Module

- Function

-

The insertion module inserts bearing hubs into a workpiece (bearing roller). The workpieces are advanced to a precisely defined position by the transfer line with the help of a baffle plate and an advancing stopper cylinder. A through-beam sensor detects the workpiece. The transfer line is stopped. The bearing hub can now be removed from the gravity-feed magazine. A handling device (linear gantry) with gripper grasps the bearing hubs and inserts them into the waiting roller. When the insertion process has been completed and the linear gantry has returned to its initial position, the transfer line is started, the stopper cylinder is retracted and the workpiece moves on.

- Pin Allocation Table

-

BMK ET200SP Profinet‑Device Designation +EFF IP-Adresse: 192.168.0.12 Installation location -1B1 I110.0 Reed switch, X-axis at conveyor belt -1B2 I110.1 Reed switch, X-axis at magazine -2B1 I110.2 Reed switch, Z-axis, gripper up -2B2 I110.3 Reed switch, Z-axis, gripper down -3B1 I110.4 Reed switch, gripper open -4B1 I110.5 Through-beam sensor, workpiece in magazine -5B1 I110.6 Through-beam sensor, workpiece in module -1M1 Q110.0 Solenoid coil, linear slide, X-axis to conveyor belt -1M2 Q110.1 Solenoid coil, linear slide, X-axis to magazine -2M1 Q110.2 Solenoid coil, linear slide, Z-axis up -2M2 Q110.3 Solenoid coil, linear slide, Z-axis down -3M1 Q110.4 Solenoid coil, gripper, open -5M1 Q110.5 Solenoid coil, stopper cylinder, advance