- General

-

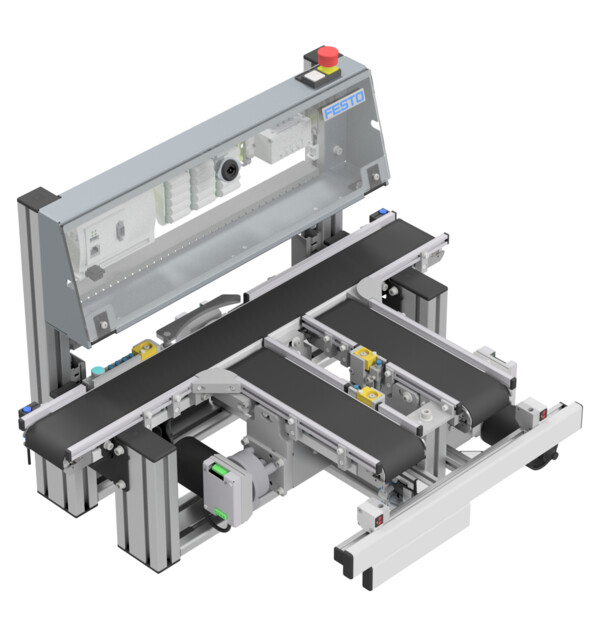

Order number D12520 Type code CP-L-BRANCH-C21 Series CP Systems Sub series CP Lab Categories Logistics

- Description

-

This station is designed to make the material flow in a CP Lab system flexible. It contains one straight belt, like CP-L-CONV, with a junction point where it connects to a dual belt. This interface between single und dual-belt systems allows transfering carriers between CP Lab and CP Factory, CP Lab and Robotino or two CP Lab systems.

-

Attribute Value Electrical connection 4 mm banana plugs Pneumatic connection Tube with 4 mm outer diameter Operating voltage 24 VDC Operating pressure 6 bar Controller Festo CECC-LK HMI Web interface I/O 14 DI / 8 onboard Single belt Stopper: pneumatic

4x Carrier detection & identification: inductive

2x Carrier detection: capacitive

2x Coupling sensors: optical (1x sender + 1x receiver each)Dual belt 2x Pneumatic stopper

2x Carrier detection: inductive3x Belt drive 24 VDC motor

bi-directional controller with slow and high speedRFID Siemens RF210R read/write head via IO-Link Other sensors 3x Light barrier for checking work piece orientation in the assembly bay Dimenions (H x W x D) mm x mm x mm -

Integrated PLC

Description Reference Datatype Address Inputs TRUE = Deflector arm closed (carrier continues straight on belt 1) +W1-BG1 Bool %I0.0 TRUE = Deflector arm opened (carrier gets diverted to belt 2) +W1-BG2 Bool %I0.1 TRUE = Stopper cylinder (belt 1) in lower end position +W1-BG3 Bool %I0.2 TRUE = Stopper cylinder (belt 3) in lower end position +W1-BG4 Bool %I0.3 TRUE = Stopper cylinder (belt 2) in lower end position +W1-BG5 Bool %I0.4 TRUE = Carrier detected at stopper (belt 2) / Carrier has left critical section via belt 2 +W1-BG6 Bool %I0.5 TRUE = Carrier detected at stopper (belt 3) +W1-BG7 Bool %I0.6 Only with Robotino Docking-Kit: TRUE = Coupling signal from Robotino received +W1-KF8 Bool %I0.7 TRUE = Carrier detected at stopper (belt 1) / Stopper (belt 1) carrier ident code bit 0 detected +W1-BG9 Bool %I1.0 TRUE = Stopper (belt 1) carrier ident code bit 1 detected +W1-BG10 Bool %I1.1 TRUE = Stopper (belt 1) carrier ident code bit 2 detected +W1-BG11 Bool %I1.2 TRUE = Stopper (belt 1) carrier ident code bit 3 detected +W1-BG12 Bool %I1.3 TRUE = Carrier detected at conveyor entry +W1-BG13 Bool %I1.4 TRUE = Carrier detected at conveyor exit +W1-BG14 Bool %I1.5 Outputs Turn deflector arm (FALSE = let carrier continue on belt 1; TRUE = divert carrier to belt 2) +W1-MB1 Bool %Q0.0 TRUE = Move stopper cylinder (belt 2) down +W1-MB2 Bool %Q0.1 TRUE = Move stopper cylinder (belt 1) down +W1-MB3 Bool %Q0.2 TRUE = Move stopper cylinder (belt 3) down +W1-MB4 Bool %Q0.3 TRUE = Drive belt 1 in forward direction +W1-QA1:A1 Bool %Q0.4 TRUE = Drive belt 2 in forward direction +W1-QA2:A1 Bool %Q0.5 TRUE = Drive belt 3 in forward direction +W1-QA3:A1 Bool %Q0.6 Only with Robotino Docking-Kit: TRUE = Switch on coupling signal to Robotino +W1-GF8 Bool %Q0.7 -

-

-

-